In recent years, the electric vehicle industry has rapidly emerged and has become an important area in today's automotive market. Consumers' growing concern for clean energy and efficient energy utilization, as well as the government's strengthening of carbon emissions regulation, have driven the market demand for electric vehicles.

Author: Raffael Schnell, VP Product Management & Applications, SwissSEM Technologies

Zhang Qiang, SUN.KING Asia Pacific Semiconductor Technology (Zhejiang) Co., Ltd.

The market positioning of electric vehicles lies not only in their appearance and high performance, but also in the combination of innovation and green technology. These cars usually adopt the most advanced electric drive technology to provide excellent performance and high power output. At the same time, lightweight design and material selection are key features of electric vehicles, aiming to improve energy efficiency and extend battery range.

In this highly competitive market, SwissSEM's HEEV packaged SiC module has become an important technological innovation. It not only meets high power requirements, but also has a lightweight design and improves system efficiency.

The HEEV packaged SiC module uses 1200V SiC MOSFET chips, which is particularly suitable for 800V high-voltage platform applications. Its Rds(on) is only 1.8mΩ@25℃, which means it has excellent conduction characteristics, enabling it to cope with electric drive power requirements of up to 250kW. This low resistance characteristic not only helps improve the efficiency of electric vehicles, but also reduces system energy consumption, bringing users higher performance and longer driving range.

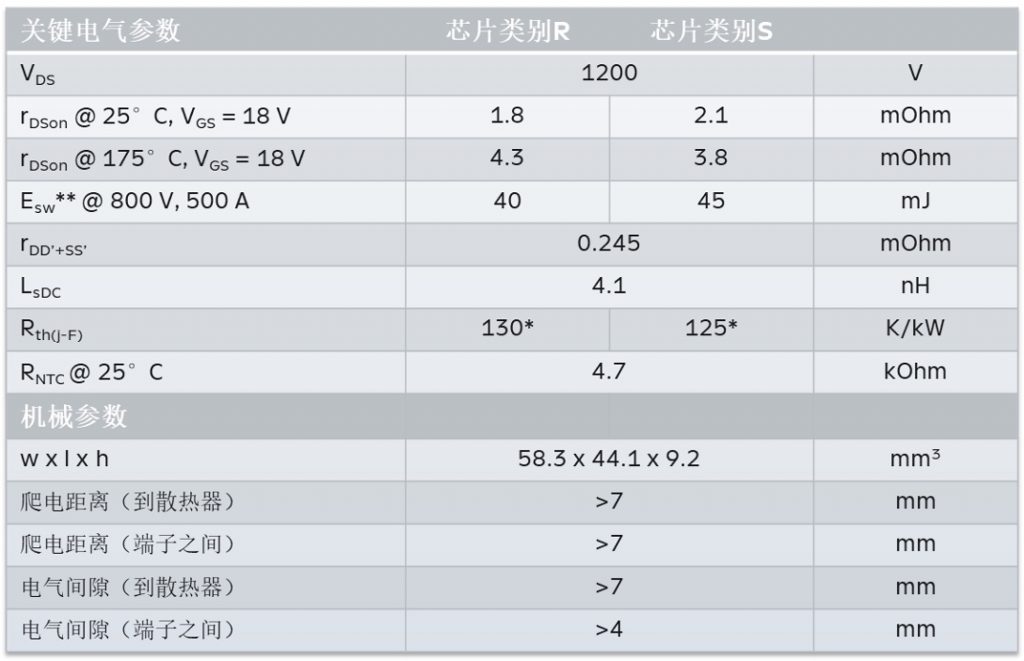

1. HEEVPackaging SiCModule static parameters

SUN.KING currently uses two types of SiC wafers that have passed automotive grade certification. The following is a comparison table of the static characteristics of these two wafers:

By optimizing the structure of HEEV packaged SiC modules, SUN.KING successfully compared with the same specification packaged modules of industry-leading companies and achieved the following three significant advantages:

① Package volume: Compared with the same specification modules provided by leading enterprises, SUN.KING's package volume is only half of that. This means that SUN.KING's package is more compact, which helps the space utilization efficiency of electric vehicle systems, while also reducing the weight of the entire vehicle and improving the carrying performance.

② Connection impedance: SUN.KING's module contact resistance (Rd+Rss) is only 0.245mΩ, while in comparison, the connection impedance of the modules of leading enterprises is 0.5mΩ. This means that SUN.KING's modules perform better in current transmission, reducing energy loss and improving efficiency.

③ Stray inductance: SUN.KING's module parasitic inductance is only 4.1nH, while the module of the leading enterprise is 6.5nH. This means that SUN.KING's modules have lower stray inductance in high-frequency applications, which helps reduce electromagnetic interference and improve system stability.

2. HEEVPackaging SiCModule dynamic characteristics analysis

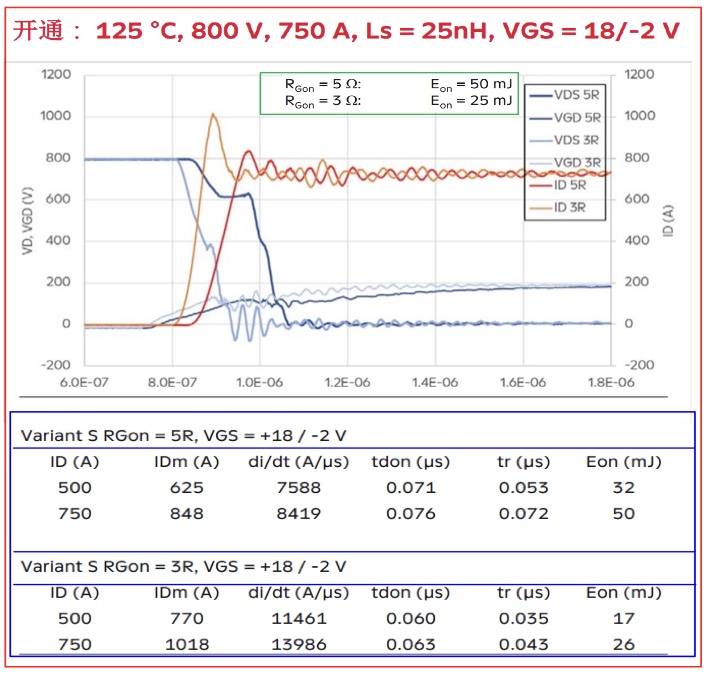

Enable features

The turn-on transient waveform and related data of the HEEV packaged SiC module at 125℃ junction temperature, 800V bus voltage, and gate resistance of 5Ω and 3Ω are shown in the figure below, which mainly include key data such as turn-on current ID, turn-on current peak IDm, turn-on di/dt, turn-on delay tdon, turn-on current rise time tr, and turn-on loss Eon.

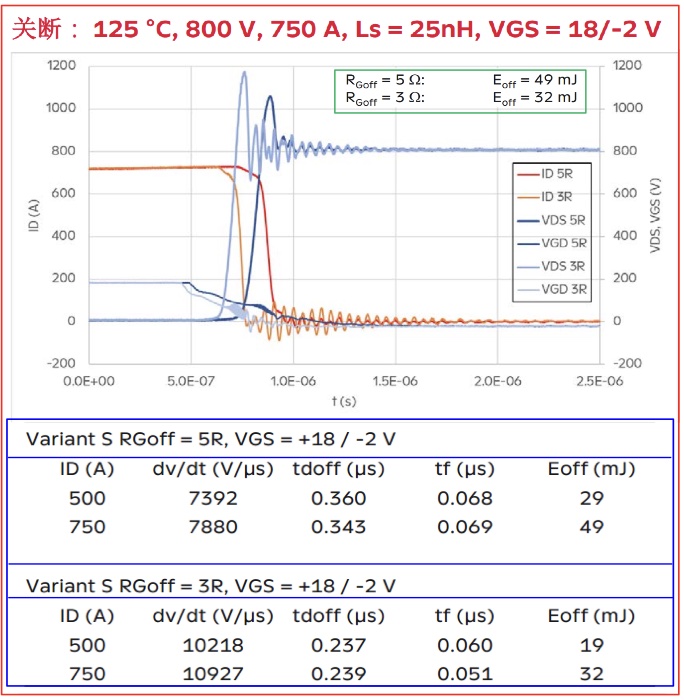

Turn-off characteristics

The turn-off transient waveform and related data of the HEEV packaged SiC module at 125℃ junction temperature, 800V bus voltage, and gate resistance of 5Ω and 3Ω are shown in the figure below, mainly including the turn-off current ID, turn-off dv/dt, turn-off delay tdoff, turn-off current fall time tf, turn-off loss Eoff and other key data.

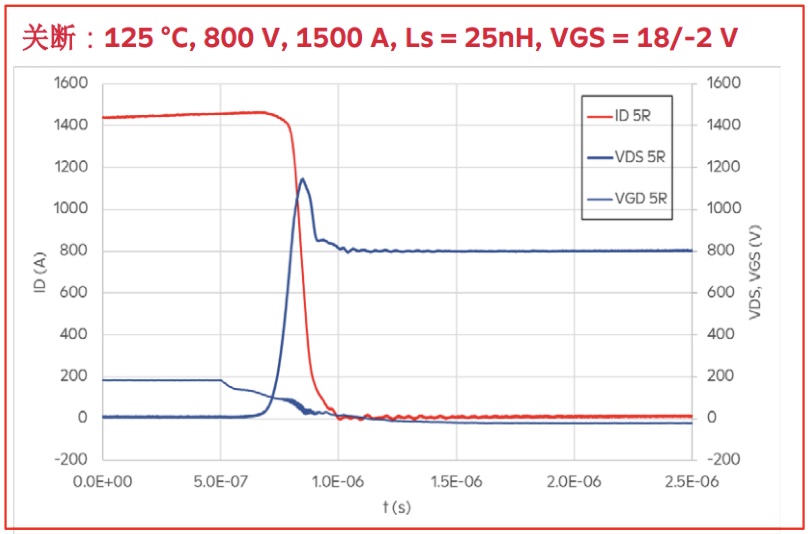

The waveform of the HEEV package SiC die turning off 2 times the rated current 1500A is shown in the figure below. It can be observed from the figure that the waveform shows no oscillation and the voltage is effectively suppressed below 1200V. This shows that the HEEV SiC module exhibits strong robustness and stability when shutting down. This is very important, especially under high current and high voltage conditions, the shutdown characteristics of the module are crucial to the safety and reliability of the system.

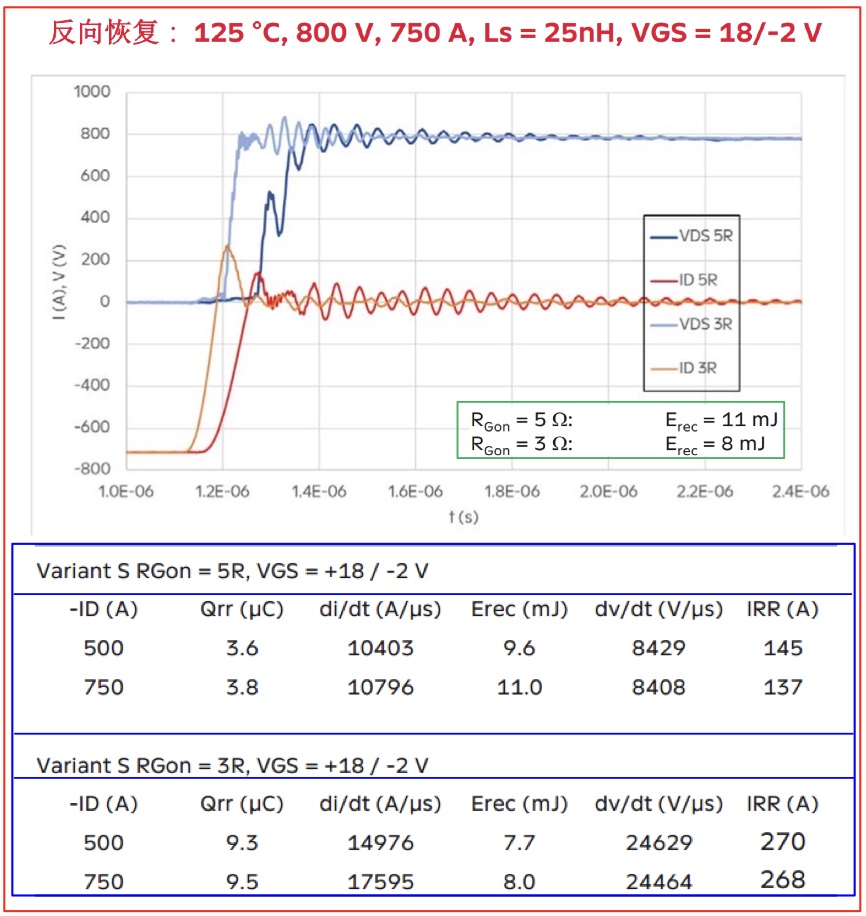

Reverse recovery feature

The reverse recovery waveform and related data of the internal freewheeling diode of the HEEV packaged SiC module at 125℃ junction temperature, 800V bus voltage, and gate resistance of 5Ω and 3Ω are shown in the figure below, which mainly includes key data such as turn-off current ID, reverse recovery charge Qrr, diode turn-off di/dt, reverse recovery loss Erec, diode turn-off voltage dv/dt and reverse recovery current IRR. These data show that the internal freewheeling diode of the HEEV SiC module has excellent reverse recovery characteristics, including low reverse recovery charge, low reverse recovery loss and fast diode turn-off speed. This is very important for improving system efficiency, reducing losses and reducing electromagnetic interference, especially under high temperature and high voltage conditions.

3. HEEVPackaging SiCModule performance

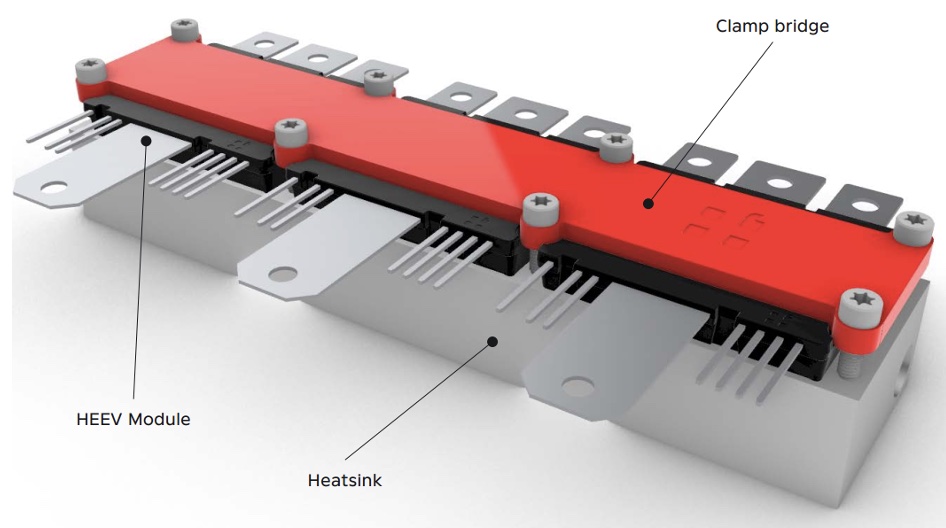

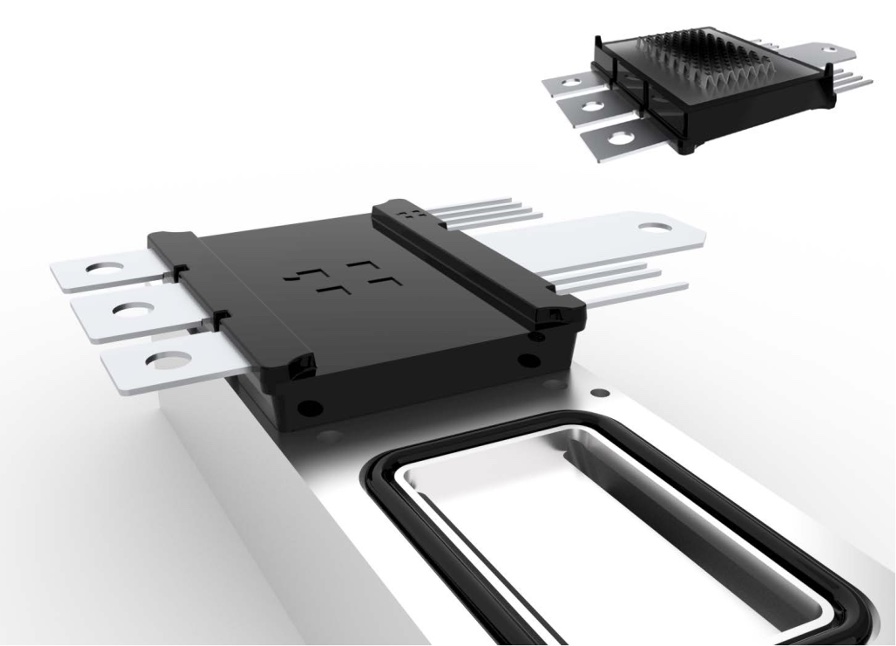

As the saying goes, "a good horse deserves a good saddle." In order to give full play to the performance of HEEV packaged SiC modules, SUN.KING has specially designed a water cooling solution for it, equipped with mounting strips. The 3D structure of the power module is shown in the figure below, which mainly includes the following three parts:

① Bridge plate: The bridge plate is one of the key components of the power module. Its main function is to firmly mount the HEEV packaged SiC module in the system and provide sufficient mechanical support. This helps to ensure that the module is not affected by mechanical vibration or shock under high-power operation, thereby maintaining the stability of the system.

② The HEEV packaged SiC module is the core of the entire power module. It contains SiC power devices and related circuits, which are responsible for transferring electrical energy from the power source to the load while achieving efficient power conversion. The performance and stability of the HEEV packaged SiC module are critical to the performance of the entire system.

③ Water-cooled radiator: The water-cooled radiator is a key component for heat dissipation. It effectively dissipates the heat of the HEEV packaged SiC module through water cooling, keeping the module within a suitable operating temperature range. This helps to improve the reliability and long-term stability of the system, especially under high load and high temperature environments.

Packaging Advantages

HEEV packaged SiC modules use a series of advanced packaging technologies and processes, with a number of advantages designed to improve their performance, environmental friendliness and life:

① Environmental friendliness: The injection molding process is adopted to make it have excellent environmental resistance. This packaging can effectively resist the impact of harsh environmental factors such as air humidity on the module, and improve the durability and reliability of the module. This is very important for applications such as electric vehicles that need to work under various meteorological conditions.

② Improve power cycle life: In order to improve the power cycle life of the module, a number of measures have been taken. The solder layer between the insulating substrate and the base plate has been removed, which reduces the thermal stress under hot pressing and helps to extend the life of the module. Advanced processes such as chip silver sintering and copper wire bonding are used to improve the reliability and thermal conductivity of the internal connection of the module, thereby further improving the life of the module.

③ Improve heat dissipation efficiency: In order to effectively dissipate heat, the module adopts a direct water cooling solution without a bottom plate. This design can quickly transfer heat to the radiator and dissipate the heat through water cooling, ensuring that the module operates within a suitable temperature range. At the same time, advanced ceramic materials are used to reduce the thermal resistance from the chip to the radiator, further improving the heat dissipation efficiency.

Excellent water cooling solution

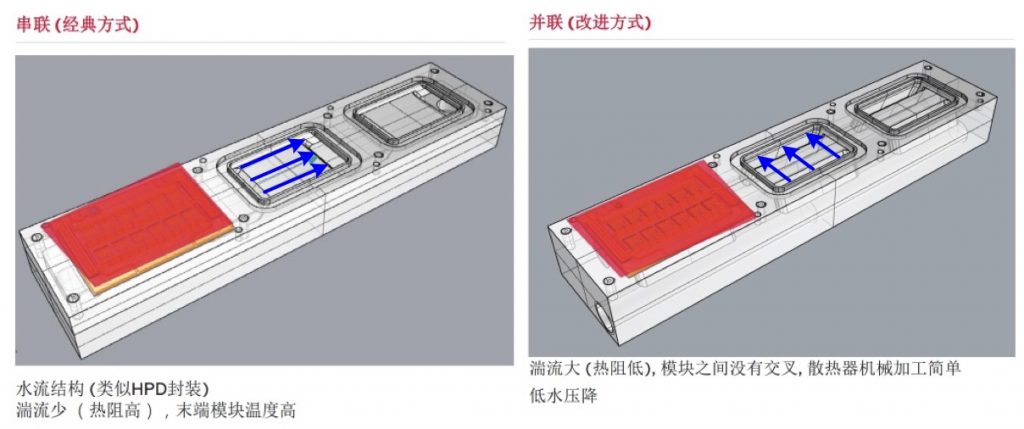

SUN.KING's HEEV packaged SiC module water cooling solution has many advantages, aiming to solve the technical problems of traditional water cooling radiators in terms of heat dissipation efficiency and module temperature balance in multi-module configurations:

① Module parallel water cooling radiator: The module parallel water cooling radiator can effectively connect multiple HEEV modules to the same cooling system. This design improves the overall heat dissipation efficiency of the system, ensures that each module can obtain sufficient heat dissipation, and avoids the problem of uneven module temperature.

② Large turbulence solution: The large turbulence solution can produce a greater turbulence effect in the coolant, thereby improving the heat dissipation efficiency. This means that more coolant will flow through the module, effectively cooling the heat of the module and reducing the module temperature.

③ Reduce module thermal coupling: By improving the design of the water cooling system, SUN.KING has successfully reduced the thermal coupling effect between modules. This means that the high temperature of one module will not have a negative impact on the adjacent modules, ensuring that each module can dissipate heat independently and effectively.

4 Patent technology support: SUN.KING has applied for relevant patents, providing legal protection for the water cooling solution, making it a unique technological innovation.

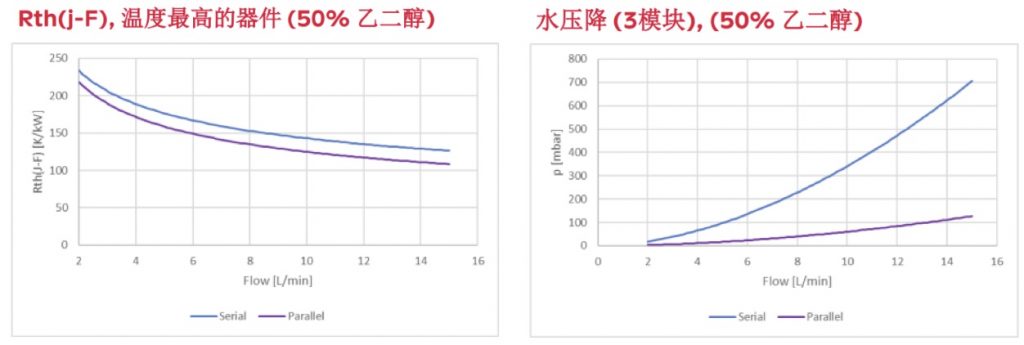

For the two cooling solutions, SUN.KING conducted CFD simulation and compared the differences between the two cooling methods. It can be seen that under the same flow rate, the parallel water cooling solution has lower thermal resistance and more uniform water pressure than the series water cooling solution, which provides a strong guarantee for improving the power density and reliability of the module.

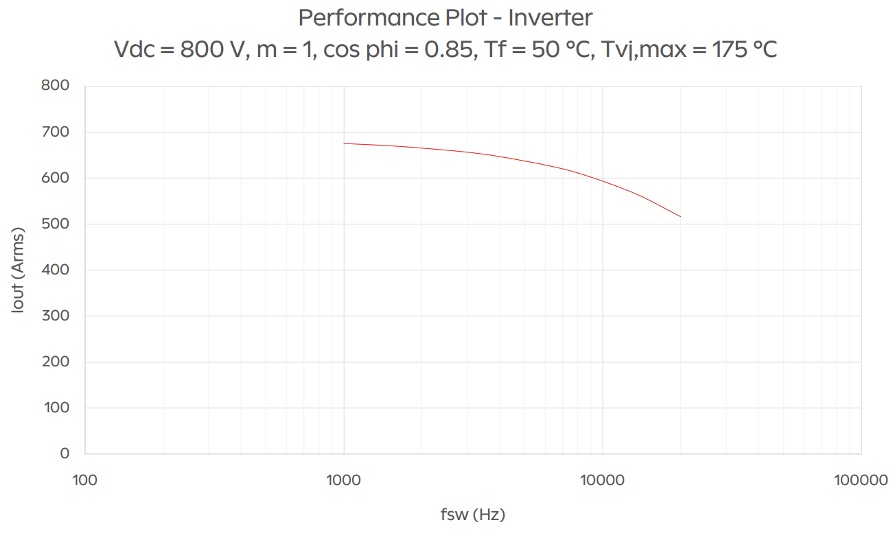

Inverter performance

The output power of the electric drive inverter based on the HEEV packaging solution can reach a maximum output power of 250kW, and the relationship curve between the output current and the switching frequency is shown in Figure 9.

Revolutionary innovation in the field of power electronics

The electric vehicle market is experiencing rapid development, and SUN.KING is actively participating in and shaping this dynamic field. SUN.KING focuses on the research and development and manufacturing of high-end power semiconductor products, including IGBT, FRD and silicon carbide chips and modules. SUN.KING's R&D center is located in Switzerland. The technical team is composed of top IGBT design and manufacturing experts from Europe and China. With decades of practical experience and excellent performance, it is one of the leaders in the field of power semiconductors.

SUN.KING's latest innovation, HEEV packaged SiC module, is designed to meet the high power, lightweight and high reliability requirements of the electric vehicle market, while taking into account the application requirements of high-performance motor drives. The development of this module is a reflection of SUN.KING's continuous pursuit of excellence in engineering and technology, providing key support for innovation in the fields of electric vehicles and power electronics.

SUN.KING's leadership and technological strength in power semiconductors will continue to drive the development of the electric vehicle industry and contribute to the future of sustainable energy and electric transportation.