Learn more

Electronics Fan Network: Electric vehicles are taking off, IGBT or SiC, which will dominate the market?

Date: 2022-09-07

<span style="box-sizing: border-box; margin: 0px; padding: 0px; font-size: In recent years, the rapid development of new energy markets such as electric vehicles, electrochemical energy storage, photovoltaics and wind power has greatly increased the market demand for power devices. In particular, the rise of electric vehicles has caused IGBT to be in a state of tight supply all year round, and there is no sign of relief in the next few years. At this time, SiC devices also took advantage of the situation and opened the road to penetration in the automotive field. So, which of these two power devices will dominate the future?

IGBT and SiC development history and market situation

<span style="box-sizing: border-box; margin: 0px; padding: 0px; font-family: " microsoft="" letter-spacing:="" in="" 1982,="" b.="" jayan="" baliga="" of="" general="" electric="" invented="" the="" igbt,="" which="" combines="" advantages="" bipolar="" power="" transistor="" (bjt)="" and="" mosfet.="" once="" launched,="" it="" attracted="" widespread="" attention.="" major="" semiconductor="" companies="" all="" them="" have="" invested="" heavily="" developing="" igbt="" devices.="" with="" continuous="" improvement="" enhancement="" process="" technology,="" its="" electrical="" performance="" parameters="" reliability="" are="" becoming="" more="" perfect.="" <="" span="">

Currently, high-frequency power devices such as silicon-based MOSFET and IGBT devices have been widely used in various fields due to their mature technology. However, with the increasing use of power devices, the performance requirements for high efficiency, high power density, etc. are also constantly increasing. In addition, the working environment is becoming more and more severe. The use of silicon devices is limited by their material properties and it is difficult to meet the needs. In order to break through the design bottleneck of traditional silicon-based power devices, third-generation semiconductor devices such as SiC and GaN have begun to emerge. Because these new materials have the advantages of wide bandgap, high saturable drift velocity, high thermal conductivity, and high critical breakdown electric field, they are particularly suitable for the production of high-power, high-voltage, high-frequency, high-temperature, and radiation-resistant electronic devices.

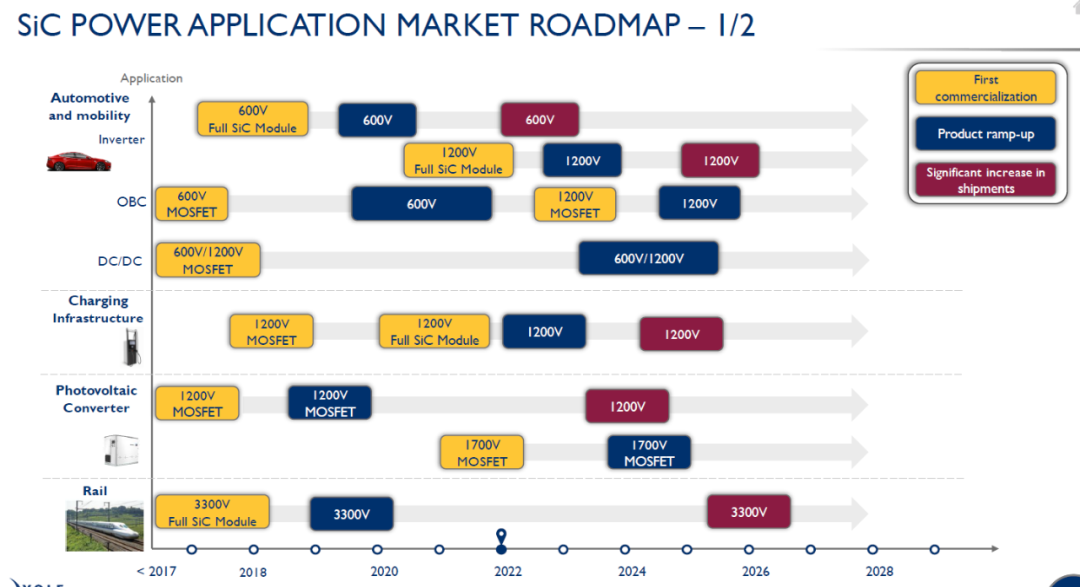

In recent years, the development of power device manufacturing technology based on wide bandgap semiconductor materials has also made rapid progress, and many semiconductor companies have launched their commercial SiC and GaN power devices. Taking SiC MOSFET as an example, the voltage range of existing commercial power devices has reached 650V~1700V, and the current level has reached 6~60A. The voltage level of SiC modules has even reached tens of kV.

According to Yole statistics, the global market size of SiC power devices in 2021 is US$1.09 billion, and the compound annual growth rate is expected to reach 34% in the next few years. By 2027, the market size will reach US$6.29 billion. It is reported that at present, SiC MOSFET is gradually penetrating in automotive OBC and electronic control. However, many companies that supply SiC modules, including OBC and MOSFET, are also suppliers of IGBT. From the perspective of market prospects, if SiC is mass-produced in the future, the output value will double, because the price of automotive SiC modules is 3 to 5 times that of traditional silicon modules, and the price of OBC single tube is twice that of silicon modules. Industry insiders predict that SiC will penetrate about 10% in the domestic electronic control field this year, and may reach 30% to 50% penetration in 2025.

Performance comparison between IGBT and SiC

As mentioned earlier, IGBT combines the dual advantages of BJT and power MOSFET. It has both the high speed of power MOSFETswitchand voltage drive characteristics, and has the characteristics of low saturable voltage drop and large current carrying of BJT, and has high voltage resistance. It is reported that the current commercial IGBT module voltage resistance has reached 6500V, and the laboratory has even reached 8000V.

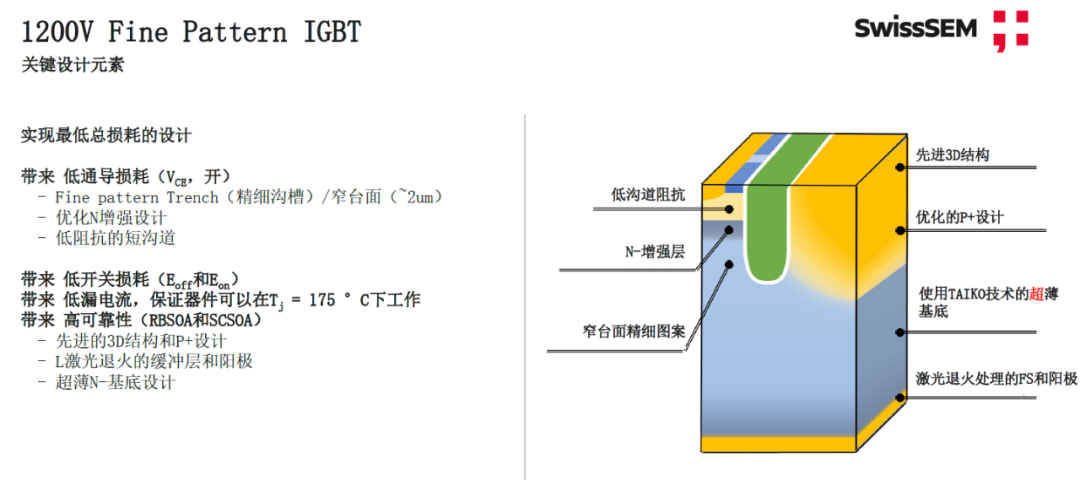

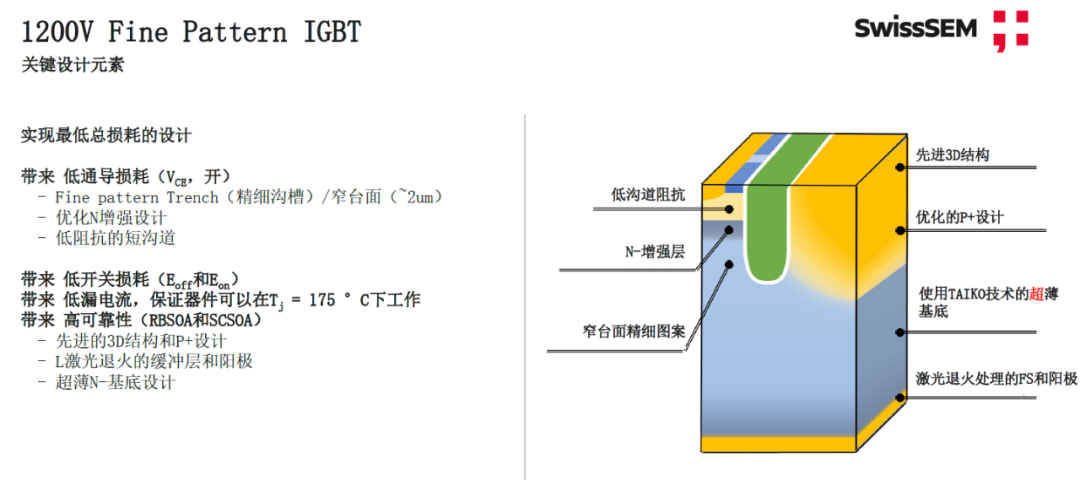

Currently, the development trend of IGBT devices is mainly high withstand voltage, high current, high speed, low voltage drop, high reliability and low cost. In the past 10 years, the main difficulty in the development of IGBT devices lies in the physical properties of the devices, especially the physical properties of trench IGBTs, which are usually not easy to achieve. It is mainly reflected in the turn-on speed and loss of IGBT, the challenges of expanding to 8-inch and 12-inch manufacturing/processing technology, the composition of the buffer layer, and the design of micro-grooves.

In other words, in order to design IGBT products with better performance, it is necessary to reduce the loss of the product, improve the turn-on speed, robustness and reliability, and increase the operating temperature. At present, overseas IGBT device manufacturers, such asInfineon, ST, Mitsubishi Electric, etc. have basically mastered the field-stop (FS) + trench gate IGBT technology, and have successively launched different series and specifications of 600V~6500V IGBT devices and module products. Due to factors such as equipment and process level, domestic IGBT manufacturers are still in the catching-up stage. However, it is gratifying that many manufacturers have made good progress, such as China's SUN.KING Asia Pacific Semiconductor Technology (Zhejiang) Co., Ltd. (hereinafter referred to as "SUN.KING Asia Pacific Semiconductor"), whose i20 IGBT chipset, which has been mass-produced, has reached or even exceeded the level of the 4th generation chips of international mainstream manufacturers in some aspects.

<span according="" to="" the="" information,="" i20="" igbt="" chip="" adopts="" fine="" trench="" gate-field="" termination="" type="" (fine="" pat<="" a="">tetern Trench- Field Stdth: 560px; display: block !important;"/>

According to Yole statistics, the global market size of SiC power devices in 2021 is US$1.09 billion, and the compound annual growth rate is expected to reach 34% in the next few years. By 2027, the market size will reach US$6.29 billion. It is reported that at present, SiC MOSFET is gradually penetrating in automotive OBC and electronic control. However, many companies that supply SiC modules, including OBC and MOSFET, are also suppliers of IGBT. From the perspective of market prospects, if SiC is mass-produced in the future, the output value will double, because the price of automotive SiC modules is 3 to 5 times that of traditional silicon modules, and the price of OBC single tube is twice that of silicon modules. Industry insiders predict that SiC will penetrate about 10% in the domestic electronic control field this year, and may reach 30% to 50% penetration in 2025.

Performance comparison between IGBT and SiC

As mentioned earlier, IGBT combines the dual advantages of BJT and power MOSFET. It has both the high speed of power MOSFETswitchand voltage drive characteristics, and has the characteristics of low saturable voltage drop and large current carrying of BJT, and has high voltage resistance. It is reported that the current commercial IGBT module voltage resistance has reached 6500V, and the laboratory has even reached 8000V.

Currently, the development trend of IGBT devices is mainly high withstand voltage, high current, high speed, low voltage drop, high reliability and low cost. In the past 10 years, the main difficulty in the development of IGBT devices lies in the physical properties of the devices, especially the physical properties of trench IGBTs, which are usually not easy to achieve. It is mainly reflected in the turn-on speed and loss of IGBT, the challenges of expanding to 8-inch and 12-inch manufacturing/processing technology, the composition of the buffer layer, and the design of micro-grooves.

In other words, in order to design IGBT products with better performance, it is necessary to reduce the loss of the product, improve the turn-on speed, robustness and reliability, and increase the operating temperature. At present, overseas IGBT device manufacturers, such asInfineon, ST, Mitsubishi Electric, etc. have basically mastered the field-stop (FS) + trench gate IGBT technology, and have successively launched different series and specifications of 600V~6500V IGBT devices and module products. Due to factors such as equipment and process level, domestic IGBT manufacturers are still in the catching-up stage. However, it is gratifying that many manufacturers have made good progress, such as China's SUN.KING Asia Pacific Semiconductor Technology (Zhejiang) Co., Ltd. (hereinafter referred to as "SUN.KING Asia Pacific Semiconductor"), whose i20 IGBT chipset, which has been mass-produced, has reached or even exceeded the level of the 4th generation chips of international mainstream manufacturers in some aspects.

<span according="" to="" the="" information,="" i20="" igbt="" chip="" adopts="" fine="" trench="" gate-field="" termination="" type="" (fine="" pat<="" a="">tetern Trench- Field Steak: break-all; font-size: 16px; color: rgb(51, 51, 51) !important;">TeslaAfter Model 3 took the lead in adopting ST's SiC MOSFET devices, the demand for SiC MOSFET has been rising all the way and is currently in short supply. With the delivery and volume increase of models equipped with SIC MOSFET such as NIO ET5\ET7 and Xiaopeng G9, the high technical barriers of substrates and wafer fabs, slow capacity expansion and other factors, coupled with the increasing number of electric vehicle 800V platform models, the demand for SiC MOSFET will be further amplified, and the supply gap may be even greater in the future.

Conclusion

<p style="box-sizing: border-box; margin-top: 0px; margin-bottom: 15px; padding: 0px; font-size: 14px; It can be clearly seen that the technical performance of SiC MOSFET is better than that of silicon-based IGBT, but the overall cost of SiC is still very high, which is mainly determined by raw materials, processing and output. It is currently difficult to fully utilize all its characteristics. On the other hand, the technology of silicon-based IGBT is very mature. After more than 40 years of continuous struggle, exploration and innovation, the parameter compromise of silicon-based IGBT has reached an extremely high level, which can meet the needs of different application markets and the cost is controllable.Therefore, it is foreseeable that silicon-based IGBT and SiC devices will coexist in the market for a long time in the future. Even the electric vehicle market will greatly promote the development of IGBT and SiC devices. Due to cost and performance considerations, the two will still coexist.

Energy conservation, emission reduction and low-carbon economy will inevitably promote the vigorous development of the power semiconductor market. IGBT and SiC devices are the technological frontiers of power semiconductors. At present, the main suppliers are still concentrated abroad. Fortunately, the development momentum of domestic enterprises is also very good. For example, SUN.KING Asia Pacific Semiconductor completed its first IGBT module production line in June 2021 and achieved mass production. The ED packaged IGBT module series products manufactured by this production line have been tested by several electric vehicles, wind power, photovoltaic and industrial electronic control companies. At the end of last year, it completed mass delivery to customers in the new energy passenger car market in the form of wafers. In the middle of this year, IGBT modules were delivered in batches to new energy passenger car customers. In addition, the company's SiC MOSFET products are also being laid out, and it is expected to launch the first generation of silicon carbide modules this year.